Manufacturing Steps for Gear Shaper Cutter

2022-02-07 09:24:08

jiangxingTools

2969

Manufacturing Steps for Gear Shaper Cutter

1, turning

2, surface rough grinding

3, hobbing

4, heat treatment

5, surface precision grinding

6, bore and face grinding

7, profile grinding

8, outside diameter grinding

9, sharpening

10, profile checking

11, coating

相關(guān)文章

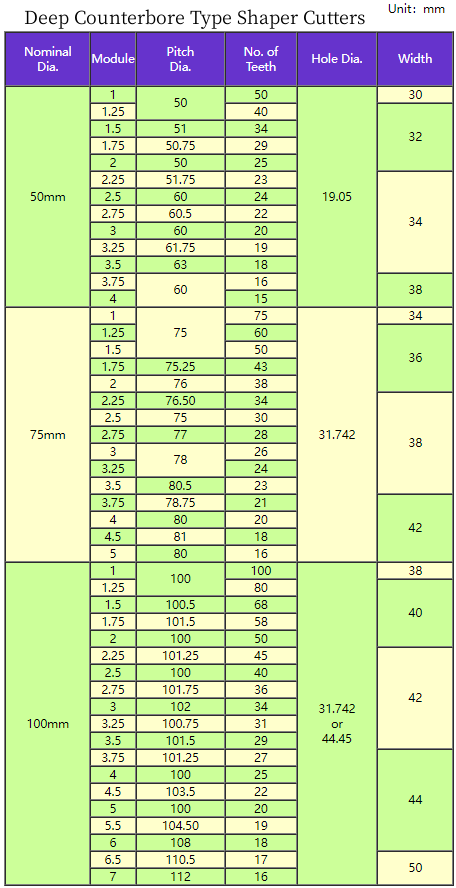

- Deep Counterbore Type Shaper Cutters with JIS B 4356

- PA20° Profile DIN3972 Standard Pre-grinding Gear Hobbing Cutter with Module m4.5

- PA20° Module m1.75 Standard Involute Gear Hob Cutter

- HSS M2E, M35, M42, ASP30, ASP52, S390 Module and DP Gear Shaping Tool with TiN, TiALN, AP

- GB 6083 Standard Gear Hobs with M2+TiN

- Gear Hobbing

- PA20° Standard Involute Gear Milling Cutter with Module m2